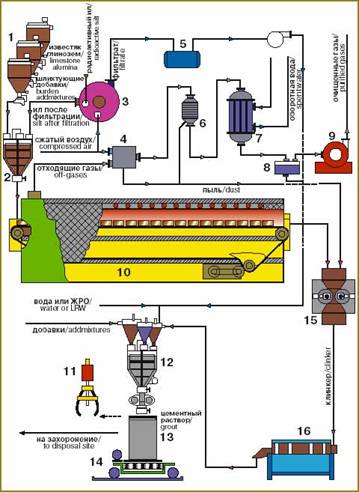

Integrated sludge conditioning facility (experimental plant)

FSUE “RADON” has developed an integrated facility for the conditioning of radioactively and toxically contaminated sludge. The facility enables conditioning of sludge which contains up to 80% of organic components as well as solid (soil, slag, crushed brick, etc.) and liquid low- and medium-level radioactive waste with a salt content of up to 1000 g/l.

The facility uses a process which synthesizes an inorganic binding material capable of chemically bonding radioactive and toxic elements. For this, the filtered sludge is mixed with saline and laminating additives with the mixture further roasted at a temperature of 700 to 1000°С and then ground.

The resultant product is mixed with LRW solutions with a monolithic compound formed in the course of solidification. The cement stone based on the synthesized binding material meets the respective regulatory requirements.

The developed integrated facility offers the following advantages:

- a 8 to 10 times as small amount of radioactive waste;

- no use of Portland cement in the process with a synthesized binding material used in its stead as the binding material;

- no secondary waste.

Process parameters

|

amount of radioactive waste in the raw mixture, % wt |

up to 90 |

|

roasting temperature, °С |

700–1100 |

|

strength of the cement stone based on synthesized binding material at the 28th day of solidification, MPa |

15–70 |

|

rate of 137Cs leaching out of the cement stone based on synthesized binding material, g/(cm2·day) |

10–4 – 2·10–5 |

Design of the integrated sludge conditioning facility

1. Bin feeder; |