Incineration of combustible solid and liquid RW

The incineration technologies developed by RADON make it possible to successfully reduce the quantities of waste and ensure reliable purification of effluent gases. The amount of radioactive waste decreases by dozens of times, the radionuclides concentrate in ash, and the ash residue is included in a highly stable matrix fit both for storage and transportation.

Radioactive waste incineration system

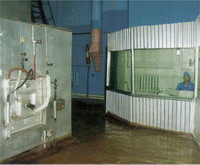

SRW is incinerated in a batch-type grate furnace with an excess of air at a temperature of 850 to 950°С. Combustible LRW (oil), which is dispersed through a separate atomizer, can be simultaneously processed in the chamber. Flue gases are destructively decomposed in the afterburner with an excess of air at a temperature of 1000 to 1200°C. The gases are then cooled to a temperature of 350 to 400°С and purified of radioactive aerosols, acidic gases and highly toxic substances. As the result, the composition of the gases released into the atmosphere meets modern Russian and international environmental requirements.

The system operation is controlled and monitored automatically. In the base version, the ash residue, flying dust and dry salts entrapped by gas purification units are cemented by grouts of a high penetration capability. To make the end product more stable, the system may be equipped with an ash residue vitrification or plasma melting unit. The layout of the system’s unit ensures the safety of activities without intermediate operations to transfer and transport the dust-forming ash residue.

Periodic inspections of the ceramic lining inner surface prove it to be in a satisfactory state after 20 years of operation in strained conditions. This confirms the validity of the designs and structural concepts adopted and high quality of the furnace refractory lining fabrication.

The Fakel incineration unit is used to incinerate combustible solid and liquid RW.

The main component is a ceramic furnace.

Capacity:

SRW incineration – 60 kg/h

LRW incineration – 20 l/h

Furnace temperature– 900 ± 50 oC

|

|

|