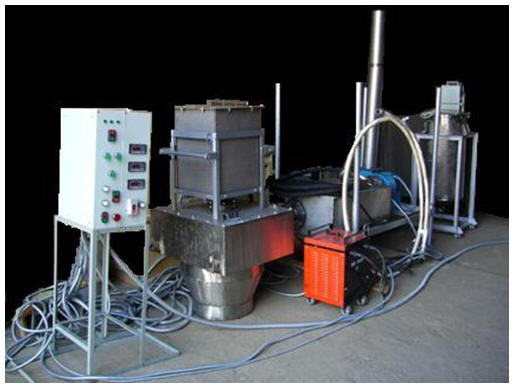

MOSKIT-T plant for conditioning of spent ionizing radiation sources (IRS)

The MOSKIT-T plant is used for immobilization of spent IRS in a metal matrix in well-type storage facilities, which enables raising storage capacity from 30,000 Ci to 180,000 Ci (in terms of 60Co). The MOSKIT-T plant allows incorporation of spent IRS into a metal matrix direct in storage facilities and in casks intended for long-term storage of conditioned radwaste. That plant can be used as well in pumping water and drying a storage facility prior to spent IRS immobilization. IRS immobilization in containers is also possible.

The MOSKIT-T plant is used for immobilization of spent IRS in a metal matrix in well-type storage facilities, which enables raising storage capacity from 30,000 Ci to 180,000 Ci (in terms of 60Co). The MOSKIT-T plant allows incorporation of spent IRS into a metal matrix direct in storage facilities and in casks intended for long-term storage of conditioned radwaste. That plant can be used as well in pumping water and drying a storage facility prior to spent IRS immobilization. IRS immobilization in containers is also possible.

SPECIFICATIONS

|

Plant type |

Modular, mobile 60 to 90 7 (max.) 100 (min.) 140 (max.) 95 (min.)5 650 (max.) 380 V, 50 Hz 20 (max.) 8 to 10 1,000 (max.) One or two persons |

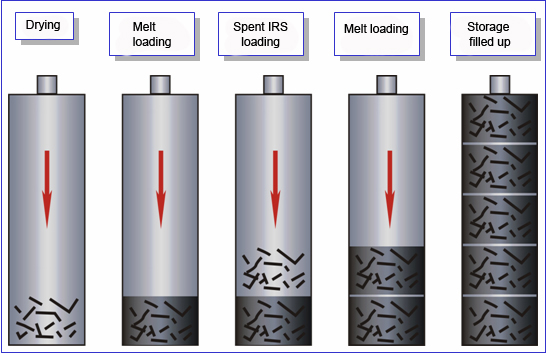

Incorporation of spent IRS in a metal matrix direct at a storage facility. Schematic

LEVEL OF DEVELOPMENT

The method in question is used at FSUE (federal state unitary enterprise) RADON since 1985. In 1991 thru 2008, conditioning work was performed at storage facilities of the Bashkir, Volgograd, Sverdlovsk and Nizhny Novgorod branches of FSUE RosRADON as well as at the Novo-Voronezh NPP and at EKORES (Belarus). In 2006-2007, the MOSKIT-T plant was mounted at the RADON Combine in Kiev and at FSUE Novosibirsk branch of RosRAO. The MOSKIT-T plant is protected by eight author's certificates and patents of the Russian Federation. The unique part of the plant is the six-meter bellows-type line, heated to 350°С, to discharge molted metal.

INTRODUCTION OF SPENT IRS CONDITIONING METHOD AT WELL-TYPE STORAGE FACILITIES